Zanzibar Project

This project will be managed under Salama Petrochemical & Oil Services Co. which is incorporated in Zanzibar.

The development of the refinery of crude oil will not only reduce the scarcity of employment in Zanzibar but also the revival and growth of economy.

Salama Petrochemical & Oil Services Co. is aiming at establishing a high class of Petroleum Refinery Plant which is anticipated to be very beneficial to the people of Zanzibar in terms of the prices of petrol, diesel, jet fuel and other matters closely related thereto.

DESCRIPTION

The objective of the project is to install a crude oil refinery with an innovative design for maximizing the profitability while using a limited feed stock supply in Zanzibar. The finished product will be naptha, kerosene, diesel fuel-oil.

Target Market:

• East Africa Countries

• Congo

• Zambia

• Malawi

• Mozambique

• Tanzania

• Comoros Island

LOCATION

The location of the project is Mangapwani in North Region Unguja. This area was chosen to develop the logistic functions of the project within the availability of proper infrastructure of transportation. This earmarked area is expected to be an influential commercial zone to faciliate the processing “plant” manufacturing unit for the refining of crude oil in Zanzibar.

• Mangapwani is North Region Unguja

• Availability of preper infrastructure

• A commercial zone which will faciliate the processing plant

DEVELOPMENT STEPS

The main activities performed during the exploitation of the site are:

• The Transportation of the Crude Oil to Zanzibar Petroleum Refinery Plant

• Production period on account of refining of crude oil

• The exploitation of social and health buildings

• The maintenance of the refinery and machinery

Advantages of the project:

• No sludge generated

• All products are recovered as saluable products

• No environmental pollution

• Availability to process any type of crude oil (light,medium,high) raw material

The estimated import of refined petroleum products in Tanzania is approximately 1.5 million tones, through port of Dar es Salaam annually.

The petroleum refinery built in this project will reduce the amount of import around 15%, annually.

Given the importance of the Petroleum products in a growing world economy and the current supply demand gap for such products, Salama Petrochemical & Oil Services Co. Trading Limited embraced a mission to engage in the establishment of a Crude Oil Refinery Plant to produce Petroleum products at Mangapwani in North Region Unguja.

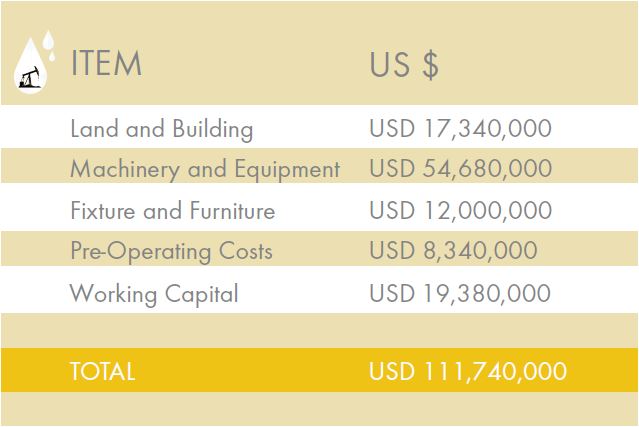

PROJECT BUDGET

The capital investment for this project is estimated 111,740,000 US $ financed through equity contribution of the promoters of this project. This capital will cover construction works, which includes Land and Building, Machinery and Equipment, Fixture and Furniture, Pre-Operating costs and working capital as shown clearly in the table on the right.

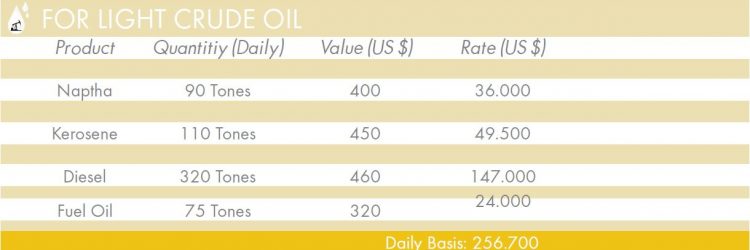

The company intends to market their products naphtha, kerosene, diesel, fuel oil with their marketing division.

Though the consumer market is experiencing an economic boom, the sales and marketing strategies were planned to grab the potential market share in the country.

Local manufacturing units in the region are very few and Salama Petrochemical & Oil Services Co. has already been in the market as sales distribution agents for diesel and various related products and having a multi-million dollar turnover for many years.

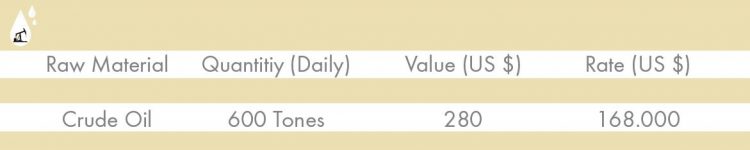

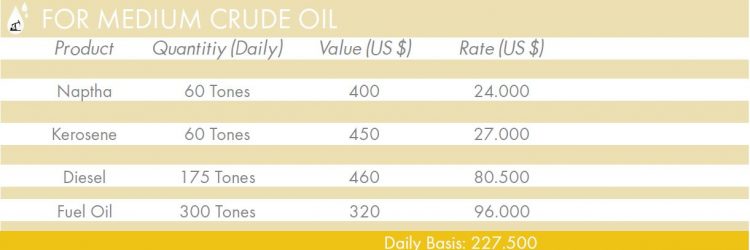

Crude Oil, different types and grades (Light, Medium, High) can be the main raw materials for the plant. Keeping in view to present market trend crude oil is available at the present rate of US $ 43~48 per barrel. The product can be purchased as per below forecast per daily bars:

SALES VALUES

Based on the market value of these products, the sales values for the products calculated as below:

According to these Sales & Market Analysis, the daily profit of the project is expected to be approximately 74.000$ on a daily basis.

The management has acquired very sophisticated machinery for the production of pure diesel and fuel oil after having various studies on the machines available for this industry and opted to acquire the state of art machinery from local and overseas suppliers at very short notice.

PLANT & MACHINERY

The total estimated cost for machinery, tank farms and site civil engineering works amounts to 111,740,000$ /= and subsequent additions are to be made during the course of completion which will require additional funds as stated earlier.

The machinery has a utilization period of 10 years and it is planned for a reserve fund to be kept in place in the forthcoming years in order to replace such machinery.

MANPOWER

Skilled employees are readily available at very short notice. Although, we may require to hire additional experienced personnel from the local community also.

Our supervisors can train the newly recruited staff to utilize their productive efforts to maintain the production with minimum supervision.

MANAGEMENT

The management has acquired vast knowledge and expertise in this field, as they were operating is the similar field in the United Arab Emirates for the past five years.

A technocrat has been appointed as General Manager to take care of entire operation of the plant, who has more than 20 years of experience in the same field.

An experienced administrative and sales and marketing team is available at short notice.

OPERATORS

A team of chemist plant operators, assistants etc. having prior experience in this field are readily available at very short notice. The commencement of the operation is scheduled from 1st of January 2016.